Three springy things are coming your way. Posted 1st class signed for today.

Good luck with it all!

Welcome to the largest Nissan Pulsar & Sunny GTI-R Forum. Masses of info, friendly members, cars for sale, lots of spares. Best forum on the net by far. Everything your gtir needs is here.

Re: Pete (the box slayer) rebuild 26th July 2016, 10:10 pm

Re: Pete (the box slayer) rebuild 26th July 2016, 10:10 pm Re: Pete (the box slayer) rebuild 28th July 2016, 11:48 am

Re: Pete (the box slayer) rebuild 28th July 2016, 11:48 am

Last edited by Cosmic73 on 30th July 2016, 10:02 am; edited 1 time in total

Re: Pete (the box slayer) rebuild 28th July 2016, 1:21 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 1:21 pm Re: Pete (the box slayer) rebuild 28th July 2016, 3:37 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 3:37 pm Re: Pete (the box slayer) rebuild 28th July 2016, 3:58 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 3:58 pm

Last edited by Cosmic73 on 30th July 2016, 10:03 am; edited 1 time in total

Re: Pete (the box slayer) rebuild 28th July 2016, 4:18 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 4:18 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 7:25 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 7:25 pm Re: Pete (the box slayer) rebuild 28th July 2016, 8:22 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 8:22 pm Re: Pete (the box slayer) rebuild 28th July 2016, 8:35 pm

Re: Pete (the box slayer) rebuild 28th July 2016, 8:35 pmMr B wrote:speak with par and get their nominal sizes for 4th .

have you measured gear contact to contact surface directly ?

have you tried stu's oem gear on shaft to confirm it reduces clearance to oem thrust shimming range ?

Also like ducie suggests, measuring at least another oem 4th would be good .

Not ideal scenario, custom thrust could be option but if par can supply a gear better sized it would be best .

Re: Pete (the box slayer) rebuild 29th July 2016, 6:01 am

Re: Pete (the box slayer) rebuild 29th July 2016, 6:01 am

Re: Pete (the box slayer) rebuild 29th July 2016, 8:55 am

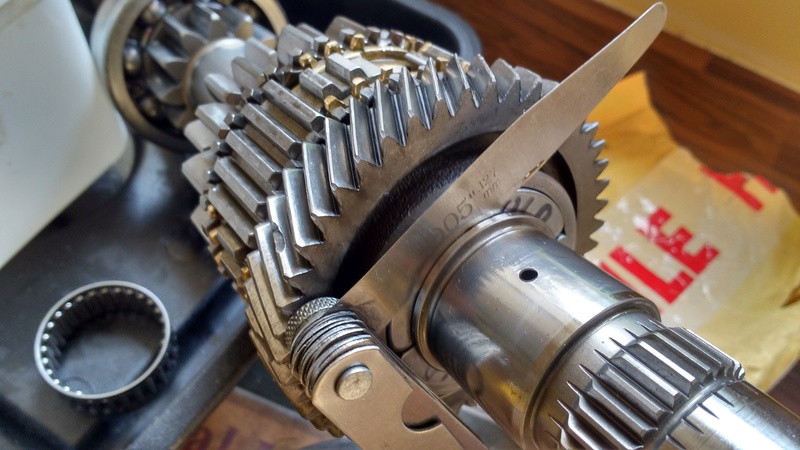

Re: Pete (the box slayer) rebuild 29th July 2016, 8:55 amMr B wrote:If the gear width contact to contact measured & spot on then it not par 4th causing excess float.

The gear cone & gear baulk ring/syncro face won't effect shaft float of gear .

Totally agree. In the manual two inspections are done on 4th.

1. Axial float is out of spec, but gear hb width which as i've stated a few times is spot on,

2, 4ths synchro face clearance with the shaft hub, which is out by 0.6mm

I suspect gear baulk ring/syncro face maybe set less on purpose to create more engagement delay/baulk ring life by par (check other gears & get specs from par)

Really? So PAR should know that this results in assembly specs not being met?

Is the syncro hub axial faces worn as that will cause excess float . par input shaft needs measuring/checking also.

No wear at all on any faces, they all looked barely run in.

Custom thrust washer will be easy way set float correct if nothing else found out of tolerance or replaceable

But if this done on purpose by PAR, why should we shim it?

2 big headaches you got is working with parts that heavily used through failed boxes and fact PARd on't supply a spec sheet or fitting notes with the kits or even have it as a pdf online :-/

not that other gearkit makers are any different !

Last edited by Cosmic73 on 30th July 2016, 11:34 am; edited 1 time in total

Re: Pete (the box slayer) rebuild 29th July 2016, 9:14 am

Re: Pete (the box slayer) rebuild 29th July 2016, 9:14 am

Re: Pete (the box slayer) rebuild 29th July 2016, 9:23 am

Re: Pete (the box slayer) rebuild 29th July 2016, 9:23 am

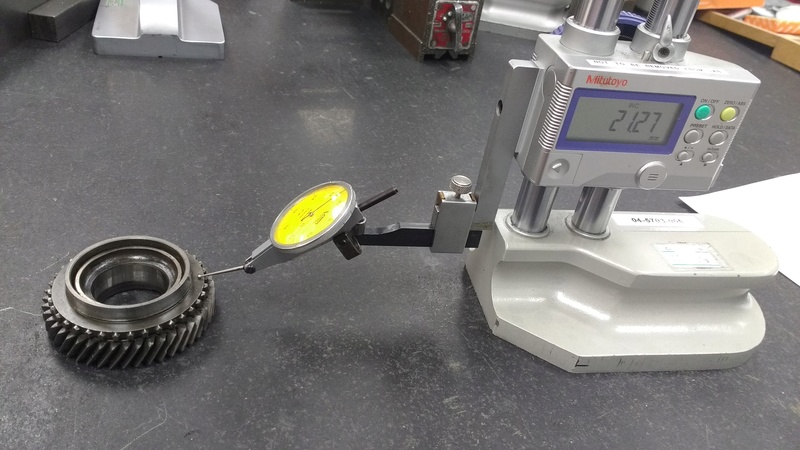

Cosmic73 wrote:Started the input shaft rebuild this morning using a small amount of MPZ lube on all friction surfaces.

3rd input gear assembled, endplay was 0.23 - 0.254 around the gear. Spec states 0.23-0.43 so it's well in even with the 0.025 run-out error.

Snap ring groove clearance less than 0.1mm so all fine.

Went on to assemble 4th and it's a different story .

Endplay 0.99mm!! Spec states 0.25-0.55,

Groove clearance 0.178!! Spec states 0.00-0.06

So Pete you need a new and thicker thrust washer. I'll measure the one you have at work next week and work out the size you need.

Re: Pete (the box slayer) rebuild 29th July 2016, 10:10 am

Re: Pete (the box slayer) rebuild 29th July 2016, 10:10 amMr B wrote:I read 4th float out of spec .

Only thing I can see off by half mil is gear synro teeth face .

What measures you get with Stu's gear on the par input shaft . Do other par gears have same offset of measure !

Re: Pete (the box slayer) rebuild 29th July 2016, 11:14 am

Re: Pete (the box slayer) rebuild 29th July 2016, 11:14 ammreguest wrote:Neil

Three springy things are coming your way. Posted 1st class signed for today.

Good luck with it all!

Re: Pete (the box slayer) rebuild 30th July 2016, 10:46 am

Re: Pete (the box slayer) rebuild 30th July 2016, 10:46 am

Re: Pete (the box slayer) rebuild 30th July 2016, 11:36 am

Re: Pete (the box slayer) rebuild 30th July 2016, 11:36 amMr B wrote:I read 4th float out of spec .

Only thing I can see off by half mil is gear synro teeth face .

What measures you get with Stu's gear on the par input shaft . Do other par gears have same offset of measure !

Re: Pete (the box slayer) rebuild 30th July 2016, 5:41 pm

Re: Pete (the box slayer) rebuild 30th July 2016, 5:41 pm

Re: Pete (the box slayer) rebuild 31st July 2016, 10:06 am

Re: Pete (the box slayer) rebuild 31st July 2016, 10:06 am

Re: Pete (the box slayer) rebuild 31st July 2016, 10:29 am

Re: Pete (the box slayer) rebuild 31st July 2016, 10:29 am Re: Pete (the box slayer) rebuild 15th August 2016, 5:25 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 5:25 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 6:34 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 6:34 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 9:11 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 9:11 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 9:33 pm

Re: Pete (the box slayer) rebuild 15th August 2016, 9:33 pm

gtir_woody wrote:Won't be any grubby filth that will cause you problems now

Similar topics

Permissions in this forum:

You cannot reply to topics in this forum