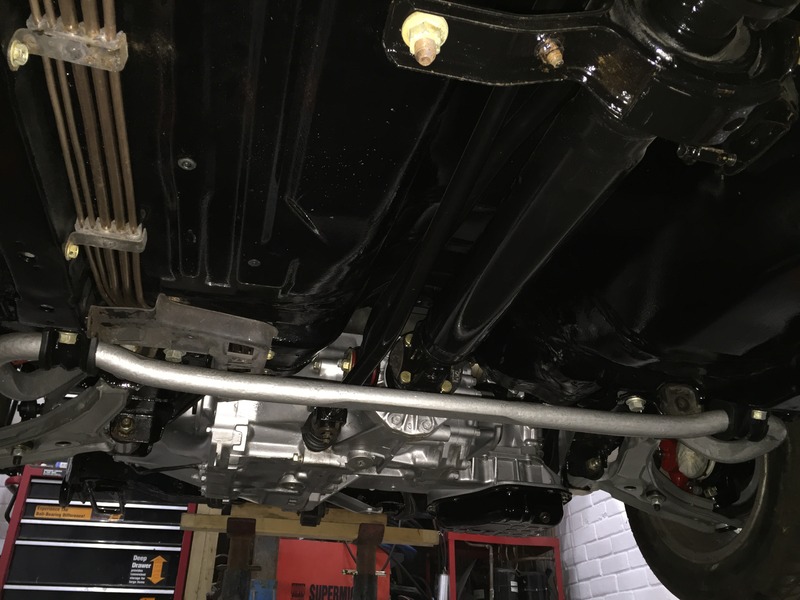

Here's my last update for a while, so nearly finished it as well, but Nissan let me down on two oil gallery bungs! Oh well..

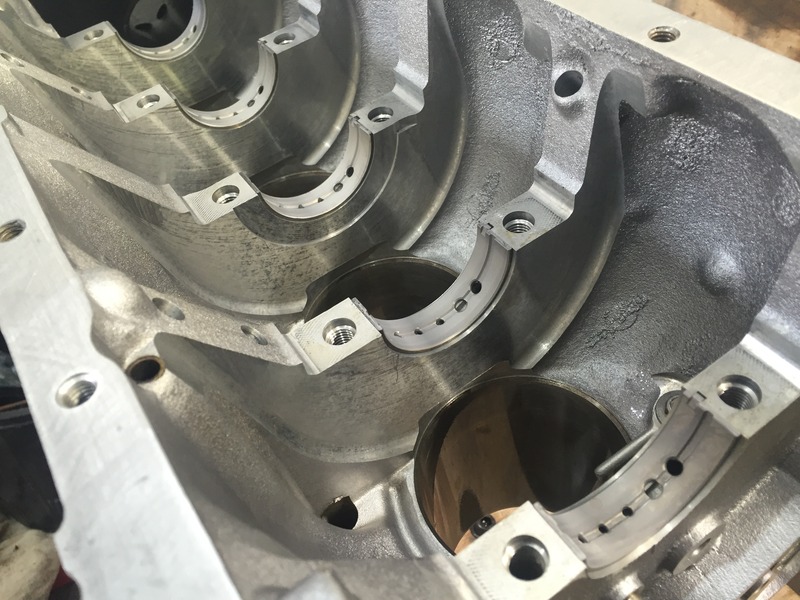

So since the last update of the shell pretty much finished I started on the engine. Stripped the thing down with the intention of only doing the head but once removing the head and discovering a spare shim balanced on the oil gallery return of the block! Intrigued I decided to strip the whole lot down, then the ocd cleaning started, acid dipped parts and zinc plating again

I always did regular oil changes and was happy to discover no burnt on oil, and generally in very good order.

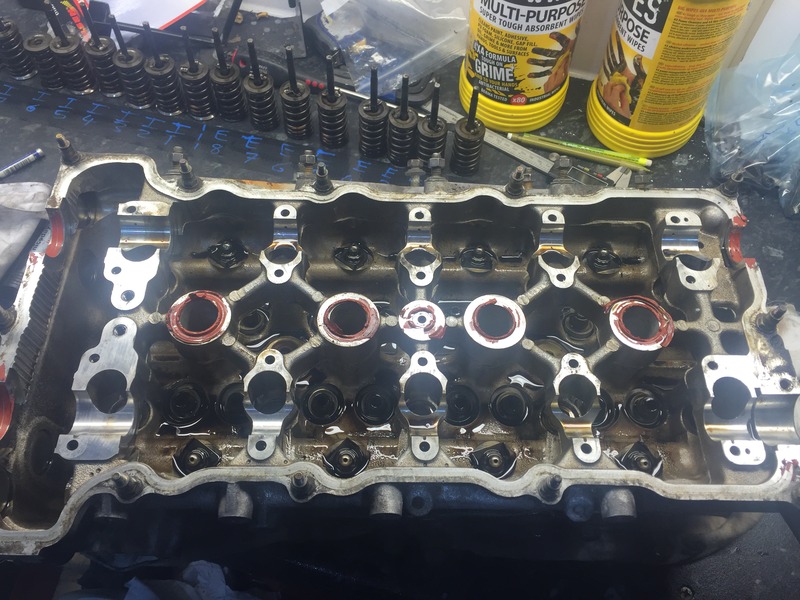

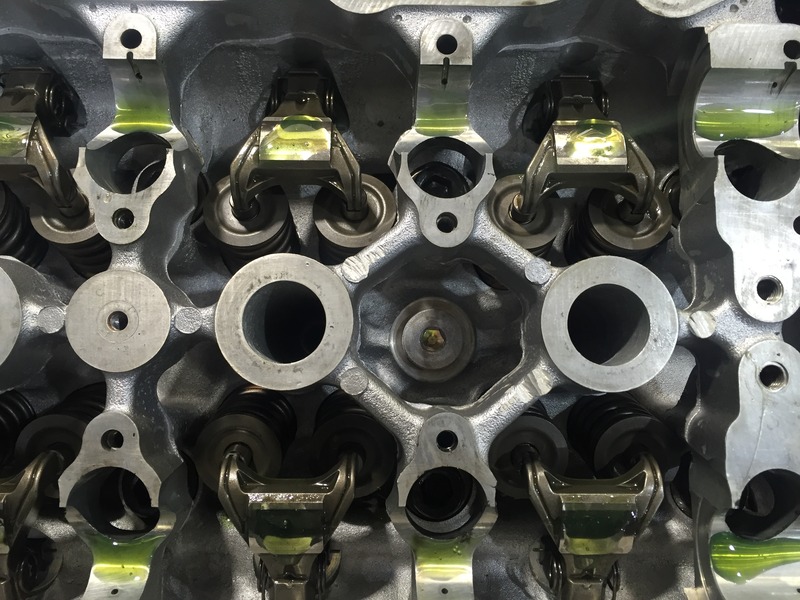

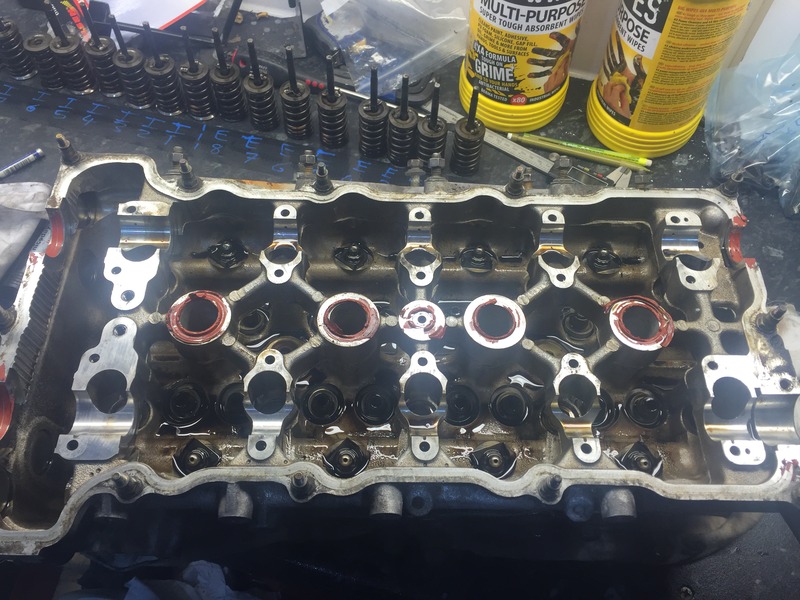

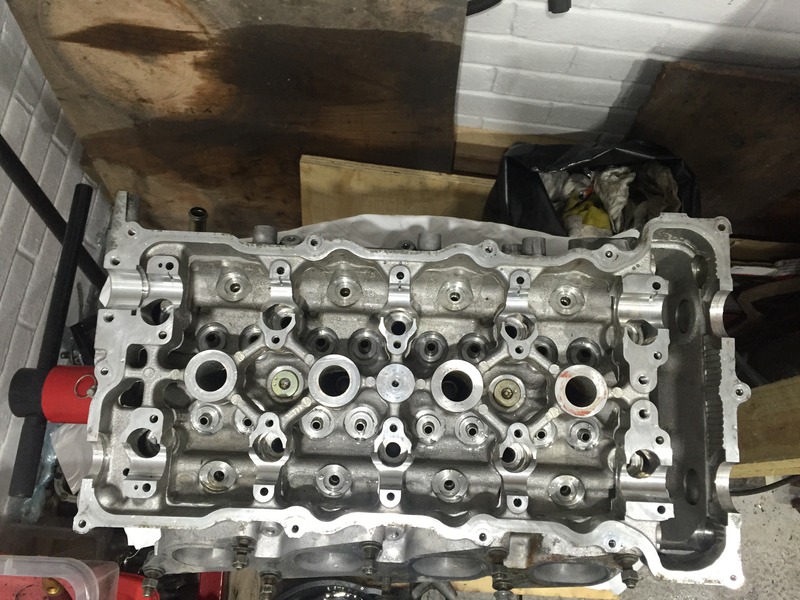

Stripped the head down, kept everything in order, measured cams, valve stems and anything else that was worth measuring. Give the head a soak in a Screwfix special degreaser. Can't believe how good the stuff is, only £7.99 bargain better than gunk in my opinion.

Boom

Said it was good stuff

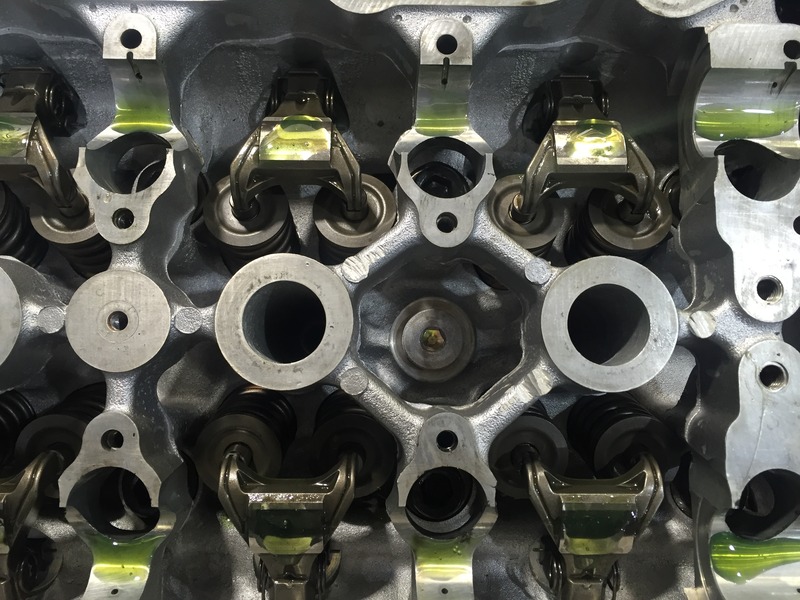

I kept a storage heater element from an old storage heater I stripped out in work to heat it up in a bucket, worked a treat. So after cleaning the head and happy with the condition of the block face I moved onto grinding in the valves, in all honesty it's the best valve seat I've seen in all the engines I've ever striped down, very little pitting and the valves also in good shape, cleaned the valves up on the lathe before lapping them in.

https://www.youtube.com/watch?v=-6Cf9dhckcA

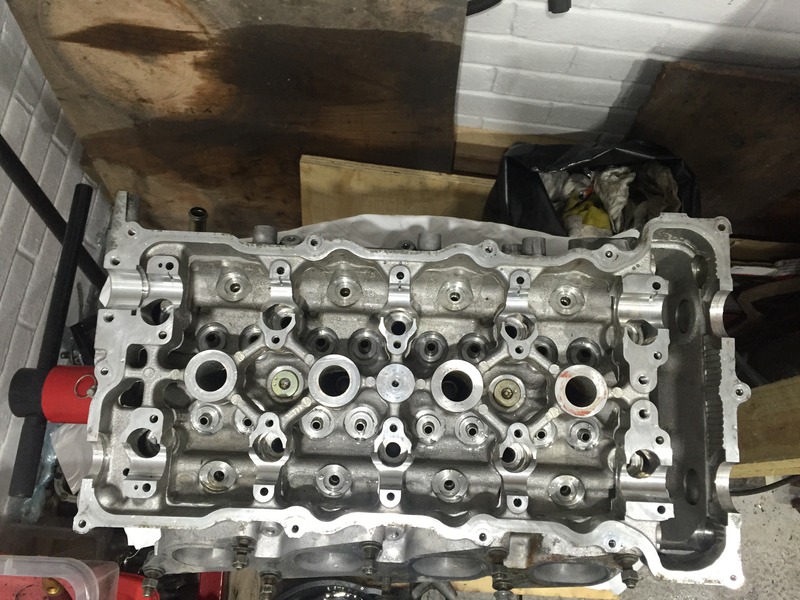

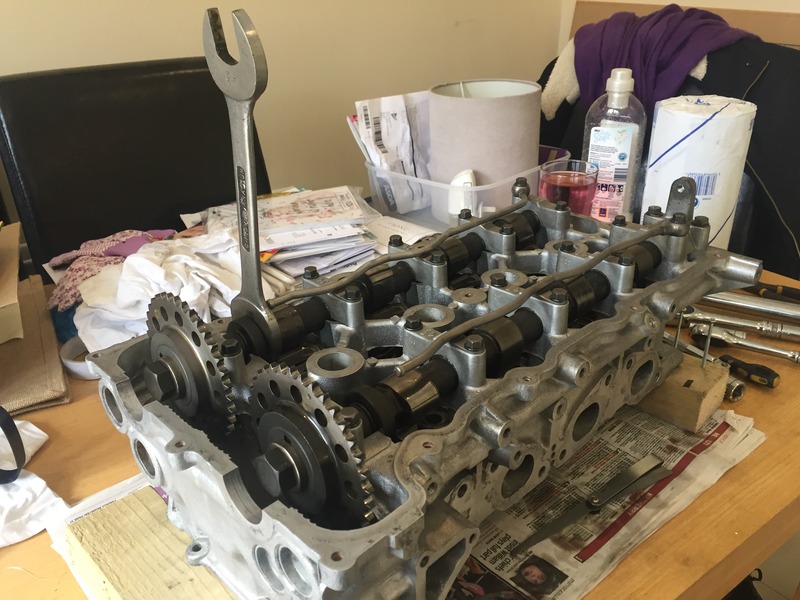

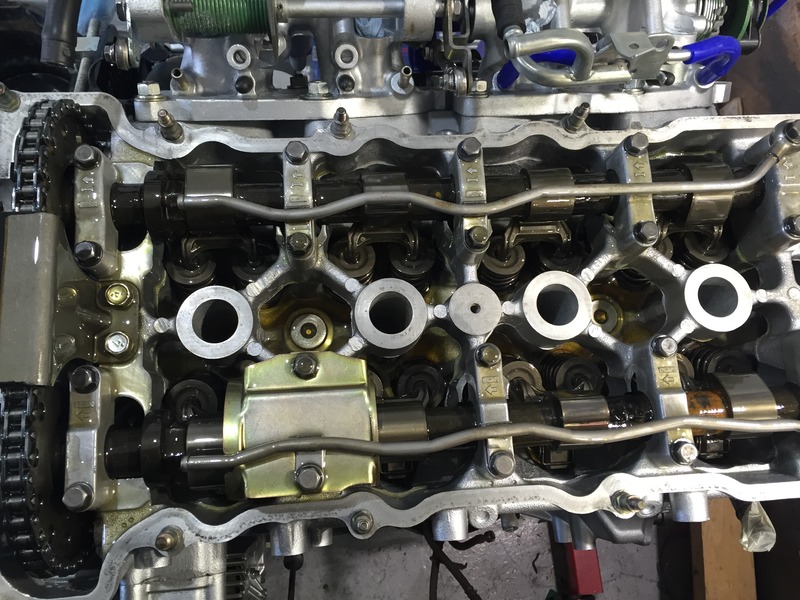

Once all lapped in the head was built back up including reshiming the head with a modified Sealey hole punch and using high quality blades. Used assembly Lube over everything and packed away in a airtight bag, well nearly air tight

And yes before anyone comments, I built it up on the kitchen table while she was in work

So then my attention moved onto the block, again heated the degreaser up and dumped the block in a under bed storage contain from B&M fitted perfect, got all the crud off then jet washed it fully, oiled the bores to stop rust. Didn't have a bag big enough so put it back onto the engine stand covered over.

fitted perfect, got all the crud off then jet washed it fully, oiled the bores to stop rust. Didn't have a bag big enough so put it back onto the engine stand covered over.

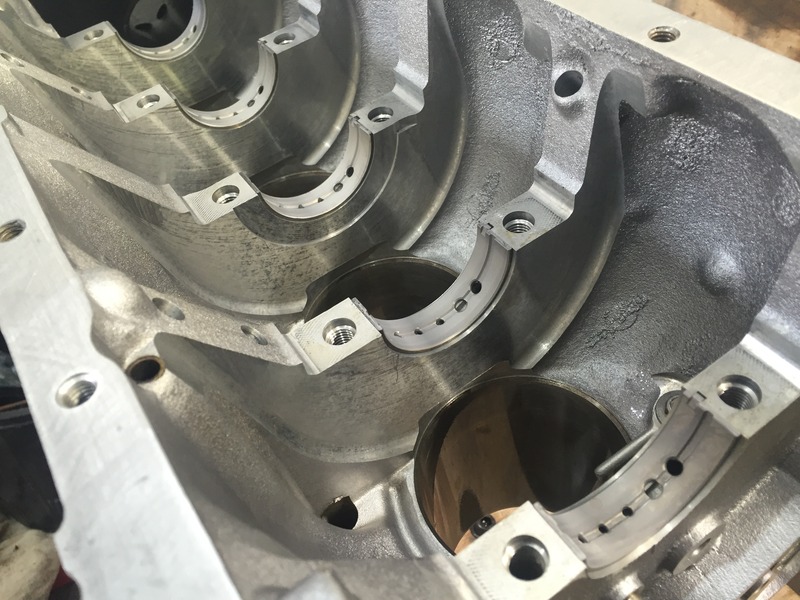

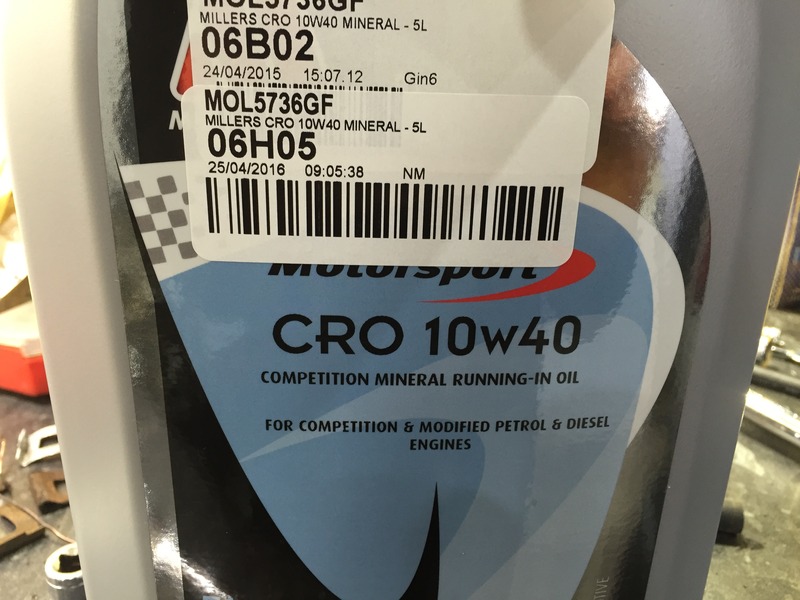

I deglazed the cylinders just before assembly commenced, mainly due to any light surface rust that had built up over the 3 months would be removed. Once deglazed another full wash to remove any tiny particles of metal. I’m no expert in deglazing and only ever done two blocks before, somehow this one made me very nervous! I won’t go into the method of how I did it, but it looked pretty spot on after, if the rings don’t seat right after then so be it, but I set out to do the whole build on my own so hopefully it works out that way and I don’t get a lot of egg on my mush!

When removing the crank, I put it into a rubble sack (without rubble), and covered it in oil to stop rusting, should have measured it before doing this, became a very messy job! But got it all measured and was within spec, then had the dilemma of what bearings to order, you may recall the thread I started of the part numbers I needed but what was stamped on the shell was different!

http://www.gtir-motorsport-club.com/t6294-selecting-big-end-bearings

Turns out when I got the new bearings they had different part number on to what I ordered and were the same as the ones removed… It took Nissan an age to get the big end bearings in, think it was around 8 weeks in the end.

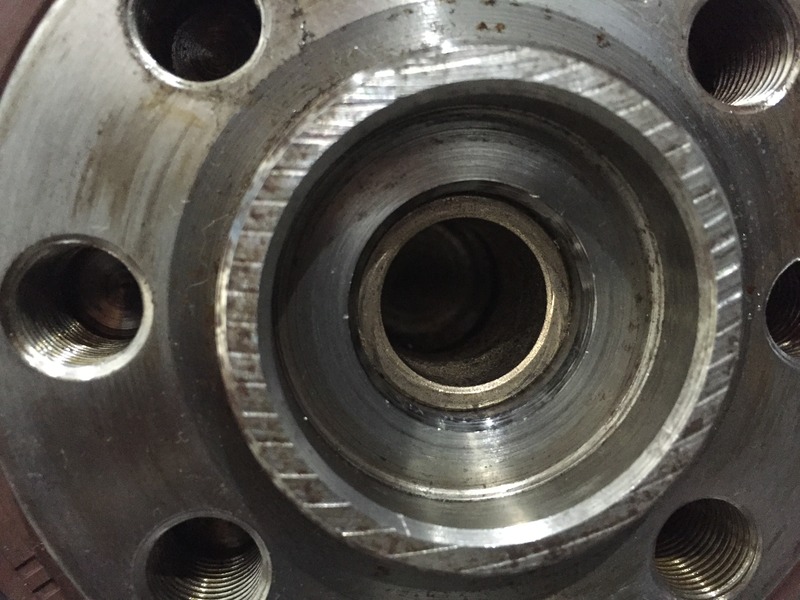

Moved onto checking the oil pump, again all clearances measured in spec, very slight pitting in the pump but very minor, should get a few more miles out of it.

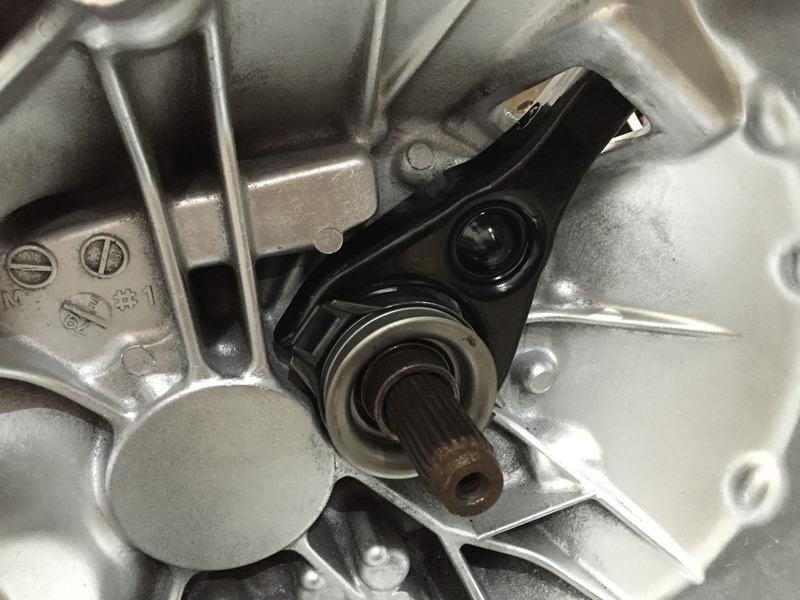

Something that’s always bothered me was a high idle that slowly came about a few years back. Had the throttle bodies off about 5 years ago to replace the hoses with Samco before they split etc. Noticed the butterflies had daylight around them when shut, thought that can’t be right, but at the time didn’t know how to cure it. This time I’d already done loads of research and put a new seal around the edge of the butterflies using Molykote 321. For once I should be able to actually use the idle screw! Before I took it off the road the idle screw couldn’t go in any further but still idled around 2k rpm. All vacuum hoses replaced, pcv valve removed and blanked etc etc etc, but still couldn’t cure it.

When stripping the throttle bodies down and looking at how they work and how the IACV works it made so much sense that the butterflies letting air past when supposedly shut will of course increase the rpm. The original grey seal on the butterflies over time wears away, which mine did, from the photos I took 5 years ago to the ones now even more had worn away. With the application of Molykote, no light can be seen through them, each throttle body has its own air hole between butterfly and cylinder fed via the IACV so will have the correct amount of air fed into each cylinder for idling.

Turbo was the next job, originally I wanted to go with a New Hybrid CHRA from Turbo Rebuild, but with finances getting tight I decided to rebuild it myself, got a 360 rebuild kit of achem ebay, sent the shaft off to turbo rebuild for balancing. Once back rebuilt it up. I only need the turbo to last a year or so, then hopefully once finances get a bit easier I can go with the hybrid turbo. I used this guide for stripping the turbo and assembling it:

http://www.sr20forum.com/turbo-guides/254779-how-rebuild-t25-t28-turbo.html

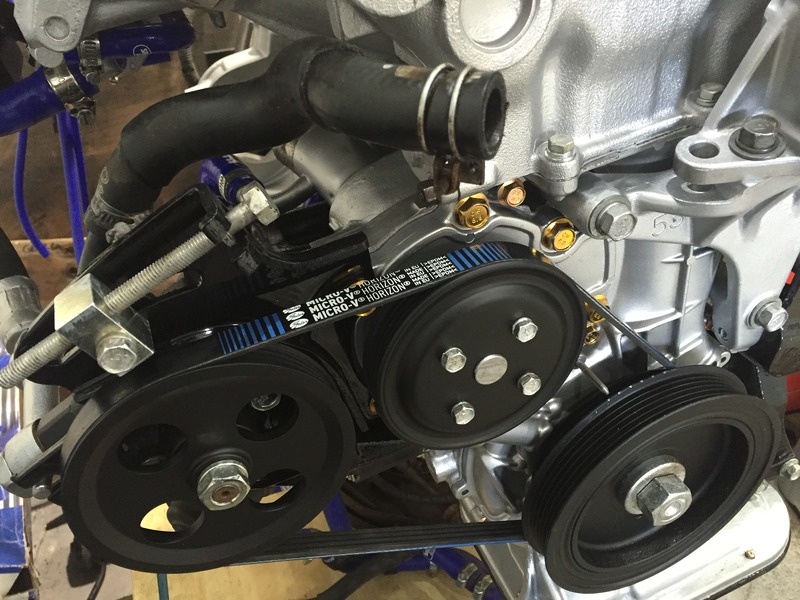

Something I toyed with for a while was whether to paint the engine or not, we all know aluminium gets a white powder over its surface over time as it oxidizes, and looks a bit pants or paint it but paint doesn’t last forever and can mark peel then look even worse.. Clearcoat would be best of both worlds but I went for paint ali colour. Problem is once I did the block and head I found I couldn’t stop!! everything started to get stripped and painted including the alternator, I knew things were getting bad when I opened the brand new Nissan water pump and painted that too

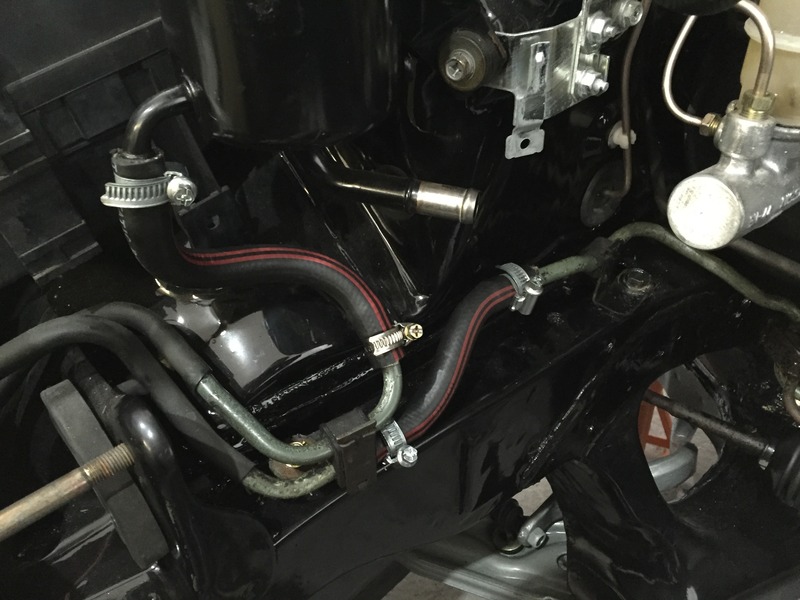

everything started to get stripped and painted including the alternator, I knew things were getting bad when I opened the brand new Nissan water pump and painted that too  all ancillary water pipes, power steering pump, oil cooler, starter motor, dizzy…. You name it, it got a coat of black or ali paint

all ancillary water pipes, power steering pump, oil cooler, starter motor, dizzy…. You name it, it got a coat of black or ali paint

Finally parts turned up from Nissan, I already had a lot of gaskets from previous rebuild kits, but likes of bearings and some O rings I had to order.

With the baby’s due date only a few weeks off, I booked a few days of work and hammered the rebuild, I wanted to get the engine built back up before I get banned from the garage for a few months.

So here’s how far I’ve got with the rebuild:

More lube

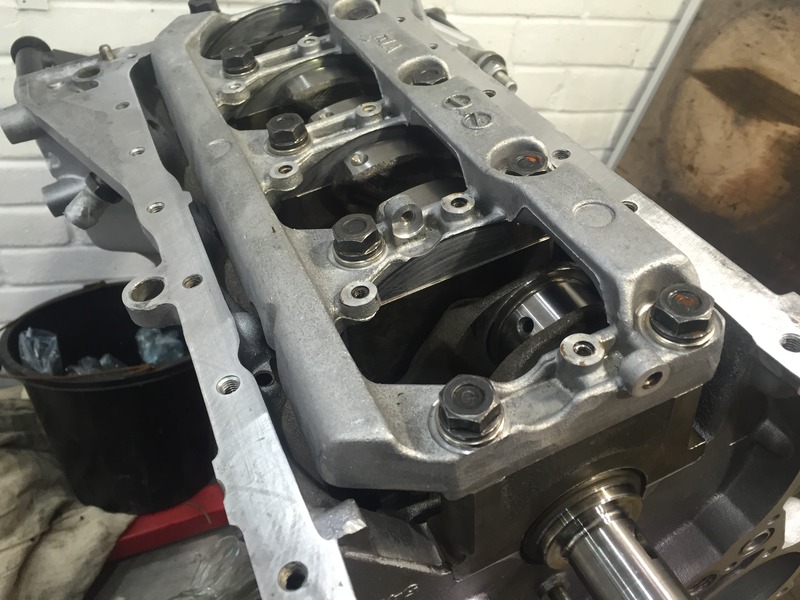

Set all ring gaps up to what the manual showed, time consuming mind (photo doesn't show the correct ring position)..

Last one to go in

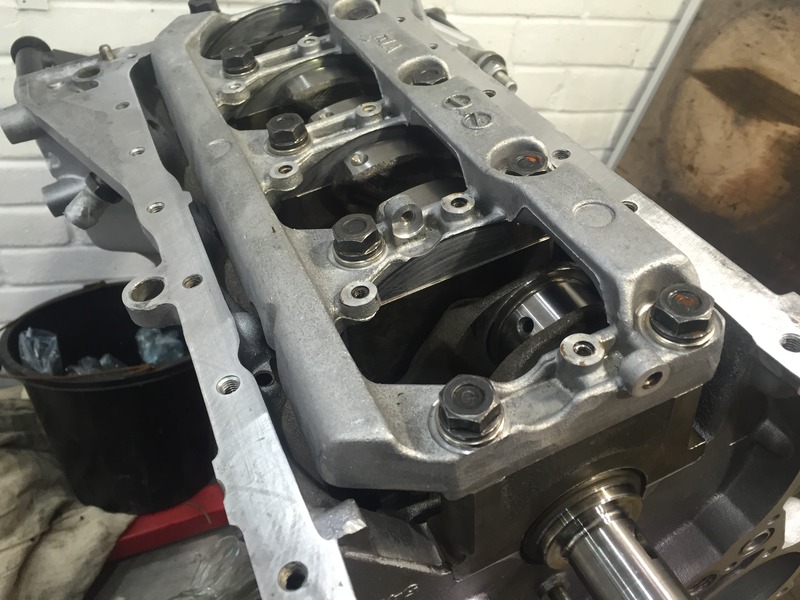

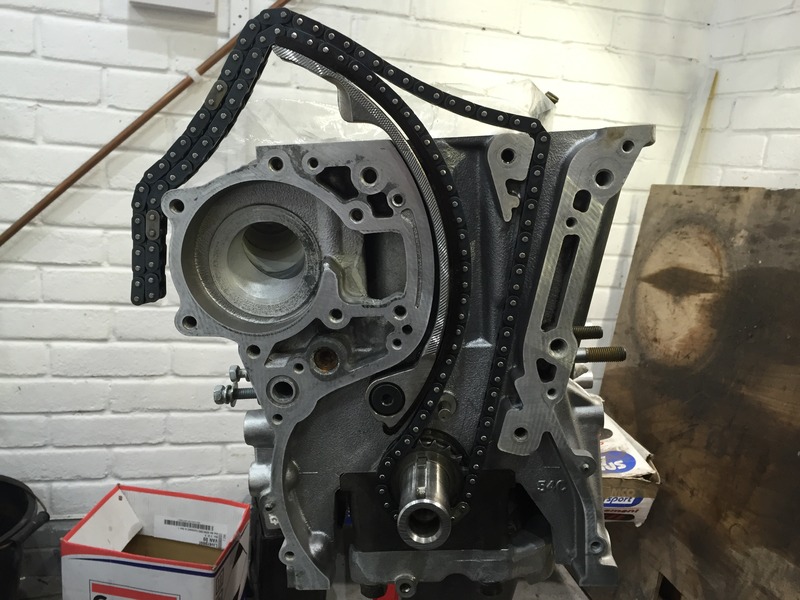

Set to TDC ready for head

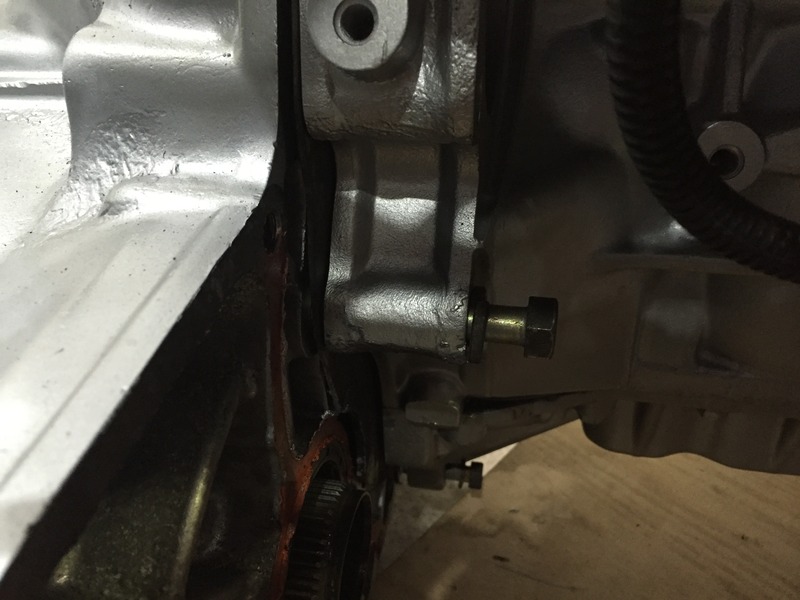

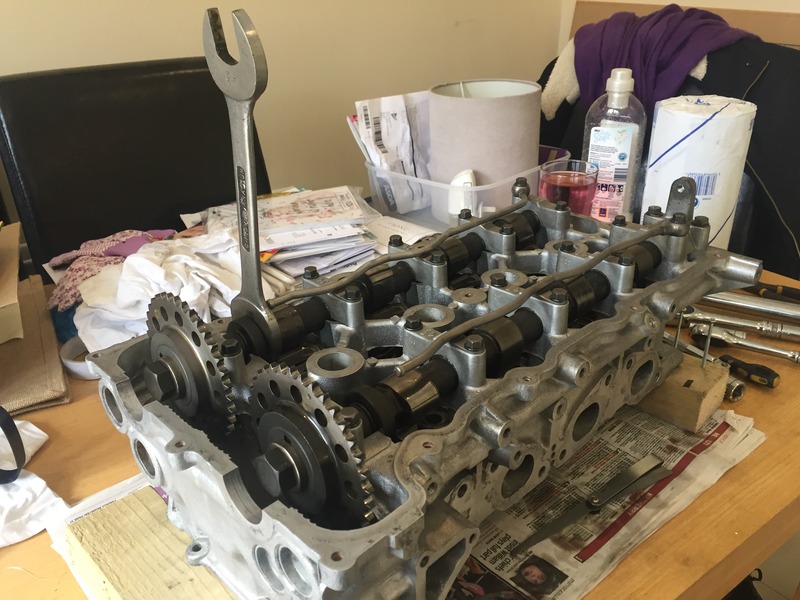

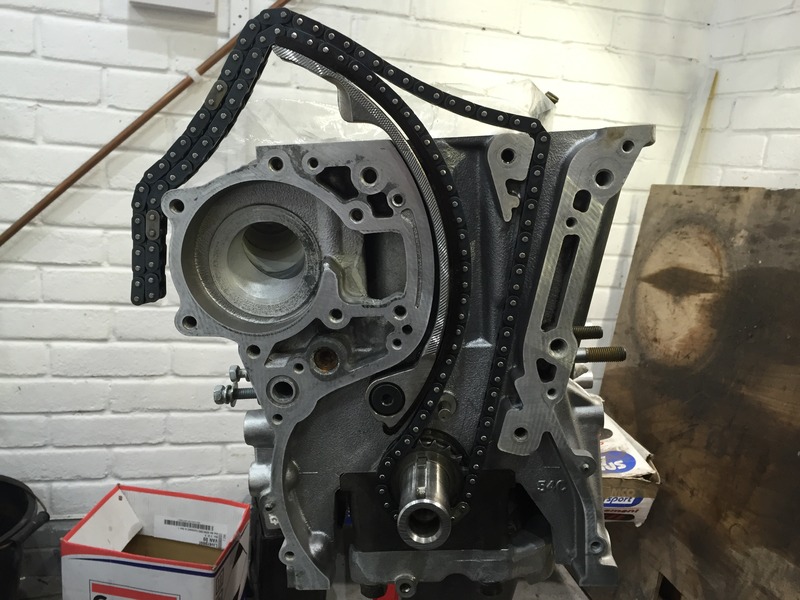

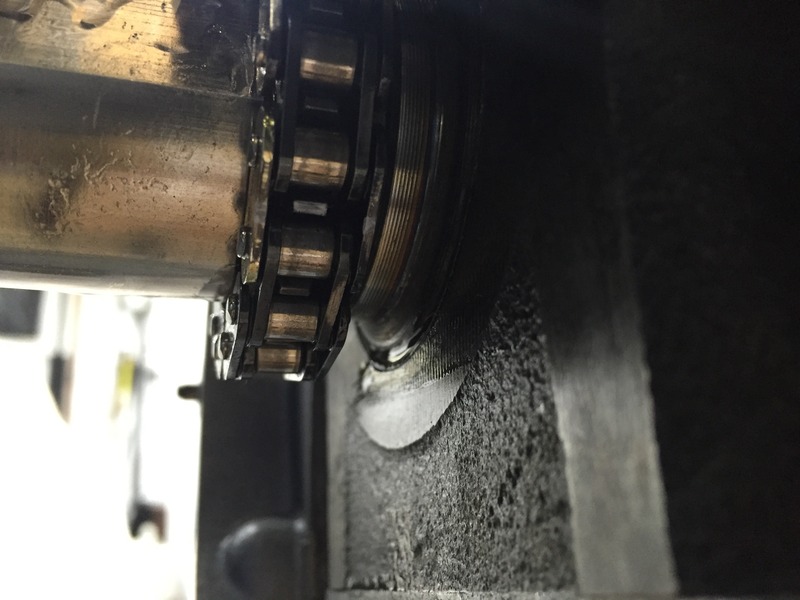

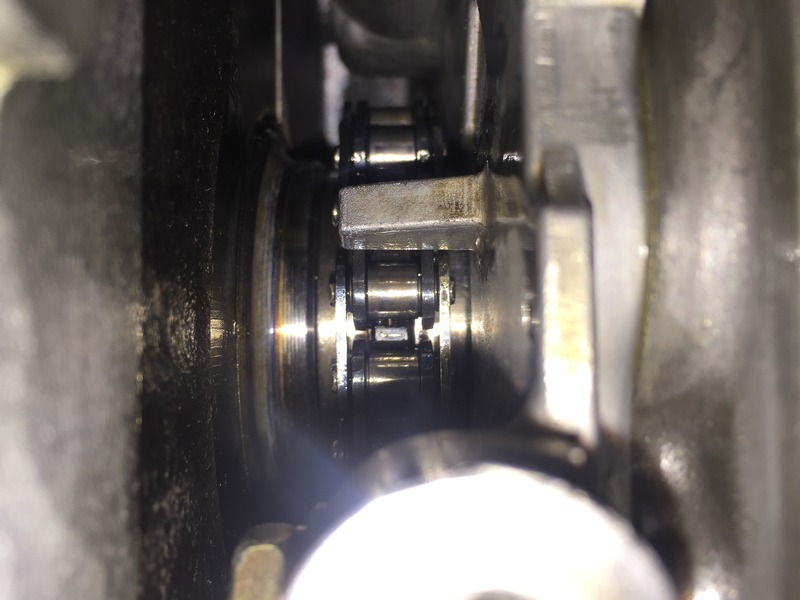

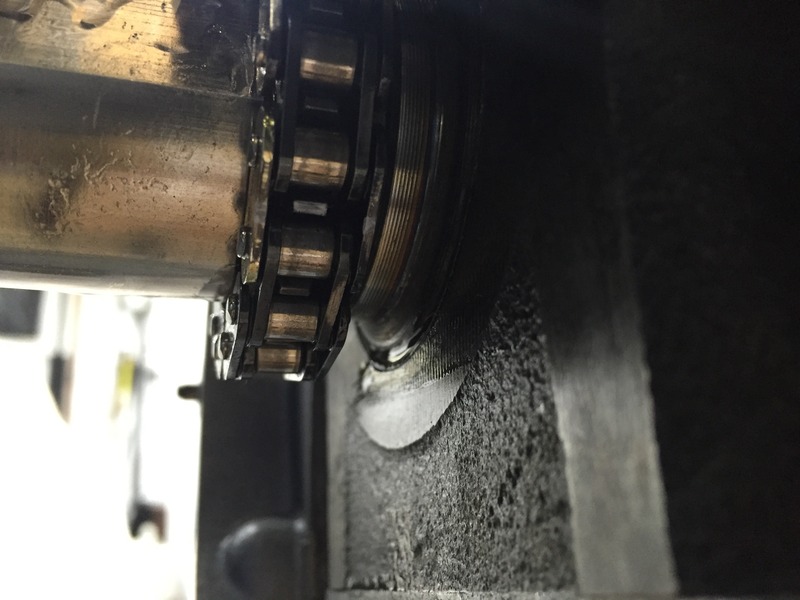

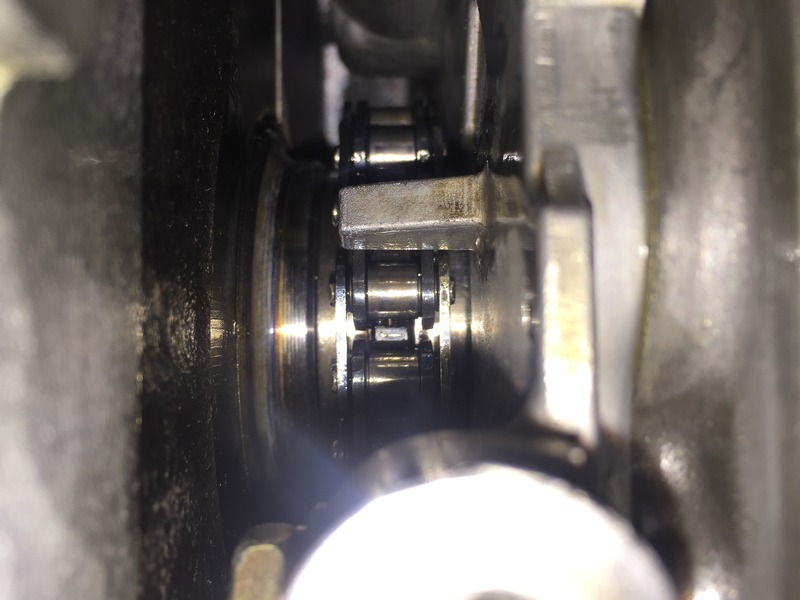

I was in two minds of how to do the chain, do I leave the chain cover off until the heads on to make sure the chain doesn’t slip off the bottom sprocket, but then have a mare trying to get the cover on?? I ended up putting the chain cover on first, but put and mark on the chain and gear tooth, so once heads on I could spin it over and check the paint marks lined up still, I can say this worked a treat!!

Time for a bit of head….. torqueing down, think I need to go the gym I bit more often , certainly takes it out of ya tightening head bolts!

More lube

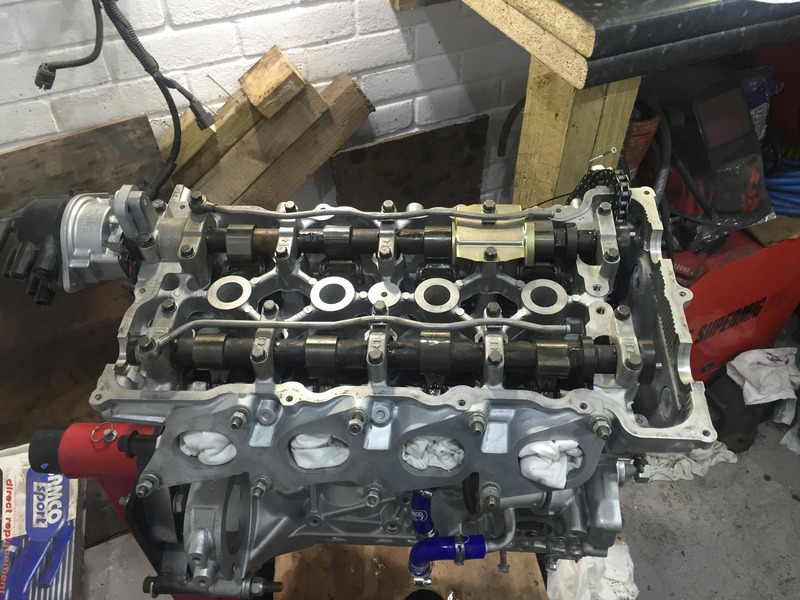

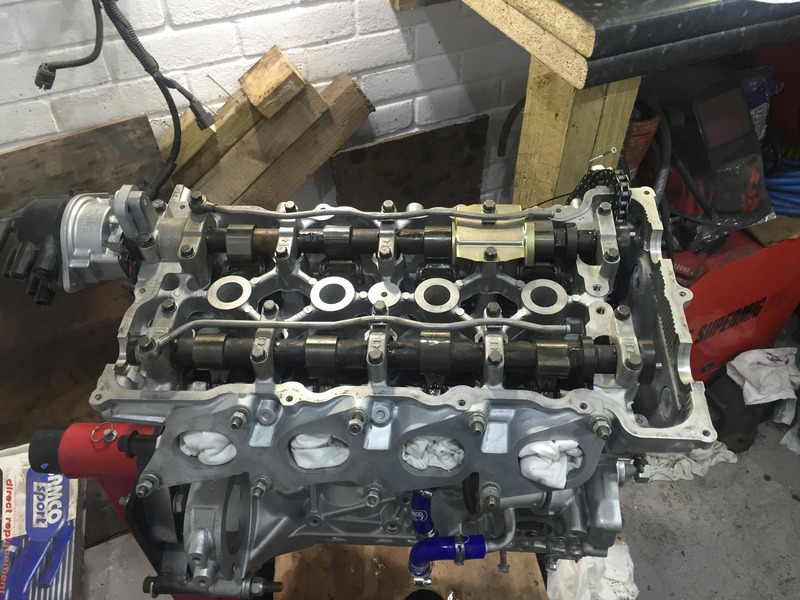

Cams in, just need to check the chain hasn’t skipped a tooth

So since the last update of the shell pretty much finished I started on the engine. Stripped the thing down with the intention of only doing the head but once removing the head and discovering a spare shim balanced on the oil gallery return of the block! Intrigued I decided to strip the whole lot down, then the ocd cleaning started, acid dipped parts and zinc plating again

I always did regular oil changes and was happy to discover no burnt on oil, and generally in very good order.

Stripped the head down, kept everything in order, measured cams, valve stems and anything else that was worth measuring. Give the head a soak in a Screwfix special degreaser. Can't believe how good the stuff is, only £7.99 bargain better than gunk in my opinion.

Boom

Said it was good stuff

I kept a storage heater element from an old storage heater I stripped out in work to heat it up in a bucket, worked a treat. So after cleaning the head and happy with the condition of the block face I moved onto grinding in the valves, in all honesty it's the best valve seat I've seen in all the engines I've ever striped down, very little pitting and the valves also in good shape, cleaned the valves up on the lathe before lapping them in.

https://www.youtube.com/watch?v=-6Cf9dhckcA

Once all lapped in the head was built back up including reshiming the head with a modified Sealey hole punch and using high quality blades. Used assembly Lube over everything and packed away in a airtight bag, well nearly air tight

And yes before anyone comments, I built it up on the kitchen table while she was in work

So then my attention moved onto the block, again heated the degreaser up and dumped the block in a under bed storage contain from B&M

I deglazed the cylinders just before assembly commenced, mainly due to any light surface rust that had built up over the 3 months would be removed. Once deglazed another full wash to remove any tiny particles of metal. I’m no expert in deglazing and only ever done two blocks before, somehow this one made me very nervous! I won’t go into the method of how I did it, but it looked pretty spot on after, if the rings don’t seat right after then so be it, but I set out to do the whole build on my own so hopefully it works out that way and I don’t get a lot of egg on my mush!

When removing the crank, I put it into a rubble sack (without rubble), and covered it in oil to stop rusting, should have measured it before doing this, became a very messy job! But got it all measured and was within spec, then had the dilemma of what bearings to order, you may recall the thread I started of the part numbers I needed but what was stamped on the shell was different!

http://www.gtir-motorsport-club.com/t6294-selecting-big-end-bearings

Turns out when I got the new bearings they had different part number on to what I ordered and were the same as the ones removed… It took Nissan an age to get the big end bearings in, think it was around 8 weeks in the end.

Moved onto checking the oil pump, again all clearances measured in spec, very slight pitting in the pump but very minor, should get a few more miles out of it.

Something that’s always bothered me was a high idle that slowly came about a few years back. Had the throttle bodies off about 5 years ago to replace the hoses with Samco before they split etc. Noticed the butterflies had daylight around them when shut, thought that can’t be right, but at the time didn’t know how to cure it. This time I’d already done loads of research and put a new seal around the edge of the butterflies using Molykote 321. For once I should be able to actually use the idle screw! Before I took it off the road the idle screw couldn’t go in any further but still idled around 2k rpm. All vacuum hoses replaced, pcv valve removed and blanked etc etc etc, but still couldn’t cure it.

When stripping the throttle bodies down and looking at how they work and how the IACV works it made so much sense that the butterflies letting air past when supposedly shut will of course increase the rpm. The original grey seal on the butterflies over time wears away, which mine did, from the photos I took 5 years ago to the ones now even more had worn away. With the application of Molykote, no light can be seen through them, each throttle body has its own air hole between butterfly and cylinder fed via the IACV so will have the correct amount of air fed into each cylinder for idling.

Turbo was the next job, originally I wanted to go with a New Hybrid CHRA from Turbo Rebuild, but with finances getting tight I decided to rebuild it myself, got a 360 rebuild kit of achem ebay, sent the shaft off to turbo rebuild for balancing. Once back rebuilt it up. I only need the turbo to last a year or so, then hopefully once finances get a bit easier I can go with the hybrid turbo. I used this guide for stripping the turbo and assembling it:

http://www.sr20forum.com/turbo-guides/254779-how-rebuild-t25-t28-turbo.html

Something I toyed with for a while was whether to paint the engine or not, we all know aluminium gets a white powder over its surface over time as it oxidizes, and looks a bit pants or paint it but paint doesn’t last forever and can mark peel then look even worse.. Clearcoat would be best of both worlds but I went for paint ali colour. Problem is once I did the block and head I found I couldn’t stop!!

Finally parts turned up from Nissan, I already had a lot of gaskets from previous rebuild kits, but likes of bearings and some O rings I had to order.

With the baby’s due date only a few weeks off, I booked a few days of work and hammered the rebuild, I wanted to get the engine built back up before I get banned from the garage for a few months.

So here’s how far I’ve got with the rebuild:

More lube

Set all ring gaps up to what the manual showed, time consuming mind (photo doesn't show the correct ring position)..

Last one to go in

Set to TDC ready for head

I was in two minds of how to do the chain, do I leave the chain cover off until the heads on to make sure the chain doesn’t slip off the bottom sprocket, but then have a mare trying to get the cover on?? I ended up putting the chain cover on first, but put and mark on the chain and gear tooth, so once heads on I could spin it over and check the paint marks lined up still, I can say this worked a treat!!

Time for a bit of head….. torqueing down, think I need to go the gym I bit more often , certainly takes it out of ya tightening head bolts!

More lube

Cams in, just need to check the chain hasn’t skipped a tooth

Last edited by burrows1980 on 15th May 2016, 8:16 pm; edited 1 time in total

Home

Home

7

7