Has anyone used npt taps before?

I have piece of 10mm aluminium flat bar, my plan is to tap 3 x 1/8 and 1 x 3/8 NPT threads into it, cut a small section out of the top of my inlet manifold and weld it in for vacuum ports.

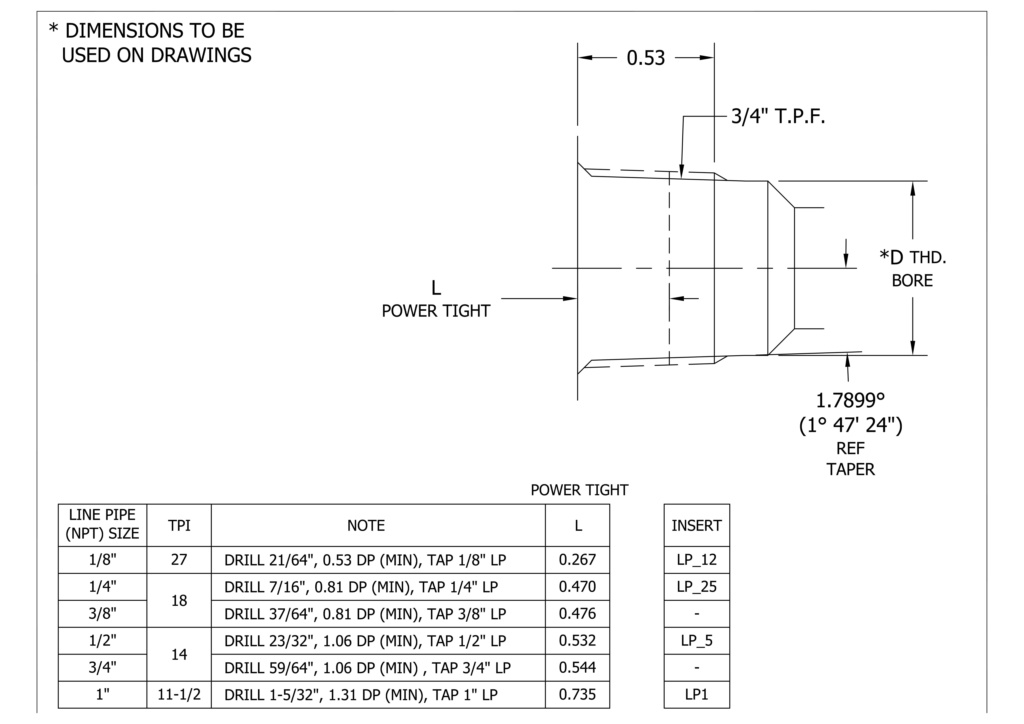

Did some googling and brought the right size drill bits, but read conflicting advice thereafter and confused the shit outta me lol

My question is how far how far do I tap? how threads/ turns are required? Is my aim to have the maximum number of thread contact when I screw the fitting in?

I have piece of 10mm aluminium flat bar, my plan is to tap 3 x 1/8 and 1 x 3/8 NPT threads into it, cut a small section out of the top of my inlet manifold and weld it in for vacuum ports.

Did some googling and brought the right size drill bits, but read conflicting advice thereafter and confused the shit outta me lol

My question is how far how far do I tap? how threads/ turns are required? Is my aim to have the maximum number of thread contact when I screw the fitting in?

Home

Home